General

ROLLING RESISTANCE

Rolling resistance is the force necessary to maintain the equipment at a constant speed. This force is inversely proportional to wheel diameter and depends on the type of bearing. It also depends upon the surface conditions and load.MOTIVE POWER

All F.I.R. castors and wheels are specifically manufactured for manual propulsion. Please refer to the manufacturer for wheels and castors required for continuous applications or powered propulsion.SPEED

F.I.R. castors and wheels nominal load capacities relate to a maximum speed of 4 Km/h ( 1,1 m/s ) - 2,49 mph (1,2 yds/s)LOAD CAPACITY

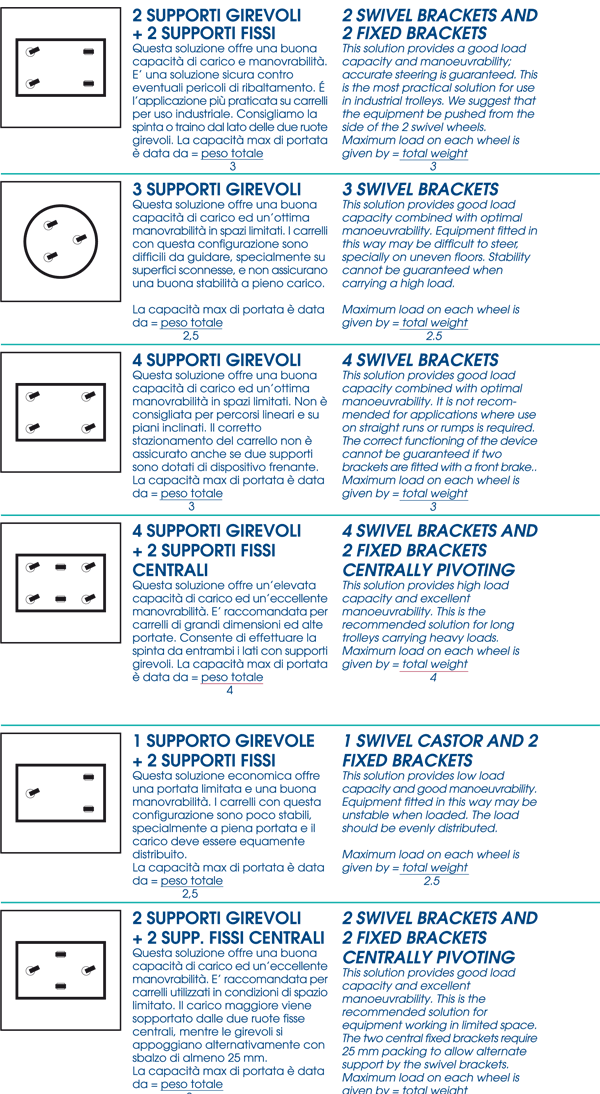

F.I.R. recommends calculation of load capacity on a single castor by use of the formula: Equipment weight + solid load / 3Equipment weight + liquid load / 2

Please apply to our technical staff in relation to load requirements close to the maximum carrying capacities

TEST CONDITIONS

Load capacities and tests are determined according to the ISO 22884, UNI EN 12527, UNI EN 12532 Standards. They refer to use under normal conditions:1) TEST LOAD = nominal load

2) TEST SPEED = 4Km/h ±50 m/h - 2,49 mph ±55 ydsIh

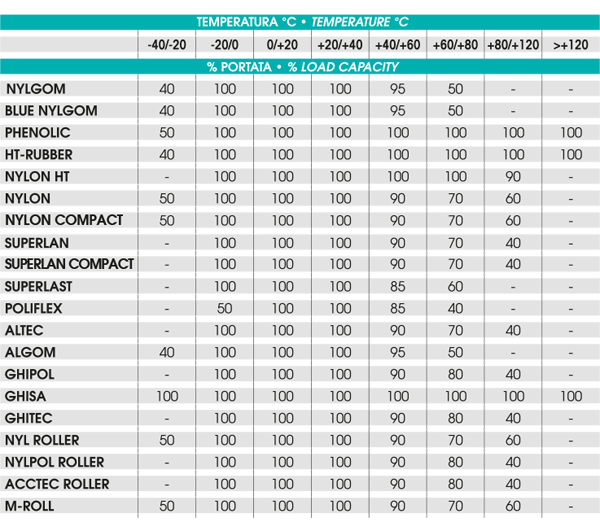

3) TEST TEMPERATURE = 20°C ±10°C - 68°F ±50°F

4) SURFACE in good conditions, hard and solid, with obstacles having the following characteristics: height equal to 5 % of wheel diameter in the case of soft tread (up to 90 Shore A); equal to 2.5% of wheel diameter, in the case of hard tread (beyond 90 Shore A).

5) CYCLE: sequence of cycles each 4 minutes maximum, included a maximum pause time of 25% of the cycle duration.

ENVIRONMENT CONDITION

F.I.R. castors and wheels are manufactured in controlled production processes using the highest quality materials. The following standard conditions are considered as “normal working conditions”:- temperature range: +5 °C to +30 °C +41°F to +86° F

- relative humidity: 40% to 80%

- no direct sunlight exposure

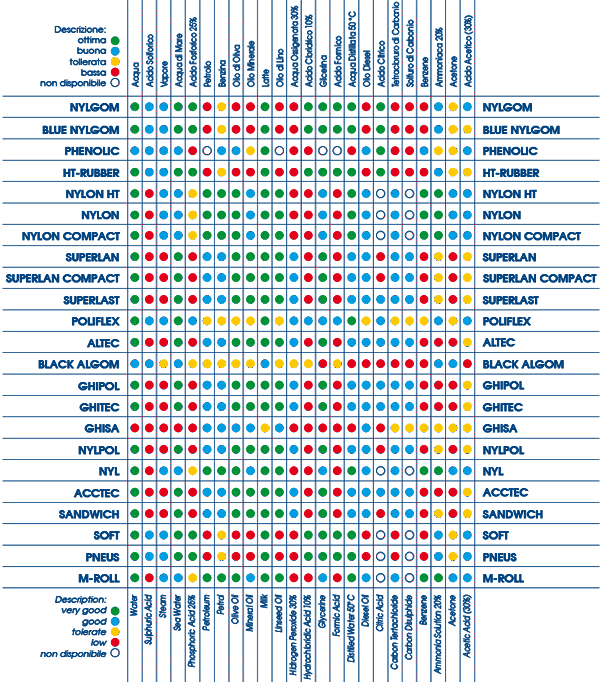

- no aggressive physical or chemical agents