F.I.R. Engineering is part of F.I.R. Fabbrica Italiana Ruote. It was created to allow the product flexibility required by the market. F.I.R. produces wheels and casters for the industrial sector. In recent years, F.I.R. has specialised in customized wheels obtained through injection molding. This type of product requires modifications of exsisting molds or building of new ones. In a very short time, F.I.R. Engineering has become a highly specialized Division, in continuous expansion, dedicated to research and innovation.

F.I.R. Engineering provides an integrated service of design, modelling, execution and testing of molds for the injection molding of plastic materials and molds for metal molding. In addition to the design and manufacture of molds, F.I.R. Engineering is also specialized in cleaning and maintenance of molds for third parties, including the reconstruction of damaged parts and productivity improvement.

F.I.R. Engineering and F.I.R. Fabbrica Italiana Ruote also provide an injection molding and metal molding service for customers.

F.I.R. Engineering collaborates with Università degli Studi di Modena e Reggio Emilia, School of Engineering ‘Enzo Ferrari’ and ITSMAKER, Istituto Tecnico Superiore, Modena.

F.I.R. Engineering is the Tooling Division of F.I.R. Fabbrica Italiana Ruote srl. It designs and manufactures molds.

F.I.R. Engineering is a highly specialized division with qualified personnel and cutting-edge technology.

F.I.R. Engineering designs and produces: single-cavity, multi- cavity, hot runner molds, cold injection molds, sliding core molds, molds for sheet metal blanking, bending, deep drawing and punching, progressive molds.

F.I.R. Engineering also carries out mold maintenance for molds produced by other manufacturers.

From the design to the finished product, from the manufacturing of the mold to molding, we provide innovative technical solutions.

We principally operate in the following sectors: industrial, pharmaceutical, cosmetic and sports equipment.

We are also specialised in mold maintenance. We carry out modifications and maintenance also for mold produced by other manufacturers.

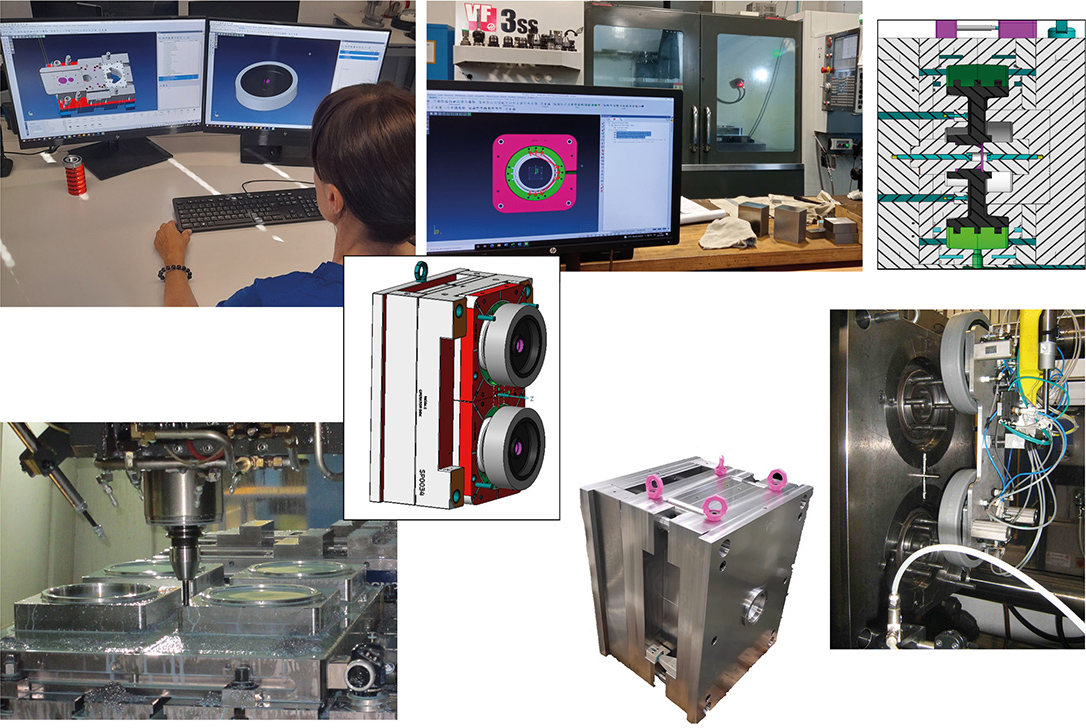

IN-HOUSE PRODUCT DESIGN, ENGINEERING, PROJECT MANAGEMENT, MANUFACTURING AND TESTING

IN-HOUSE PRODUCT DESIGN, ENGINEERING, PROJECT MANAGEMENT, MANUFACTURING AND TESTING

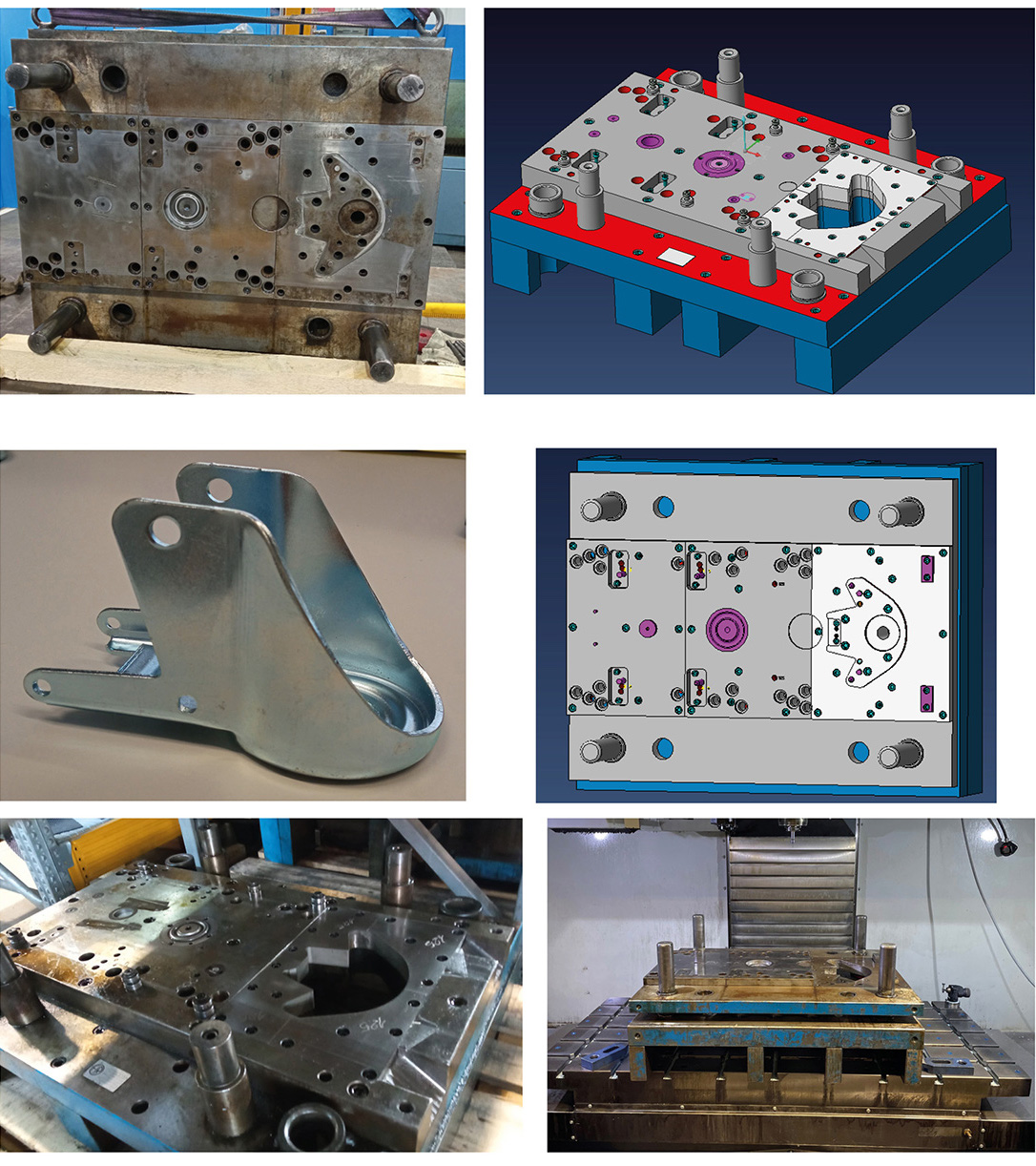

METAL MOLDING: DESIGN, CAD/CAM PROGRAMMING, EXECUTION AND TESTING

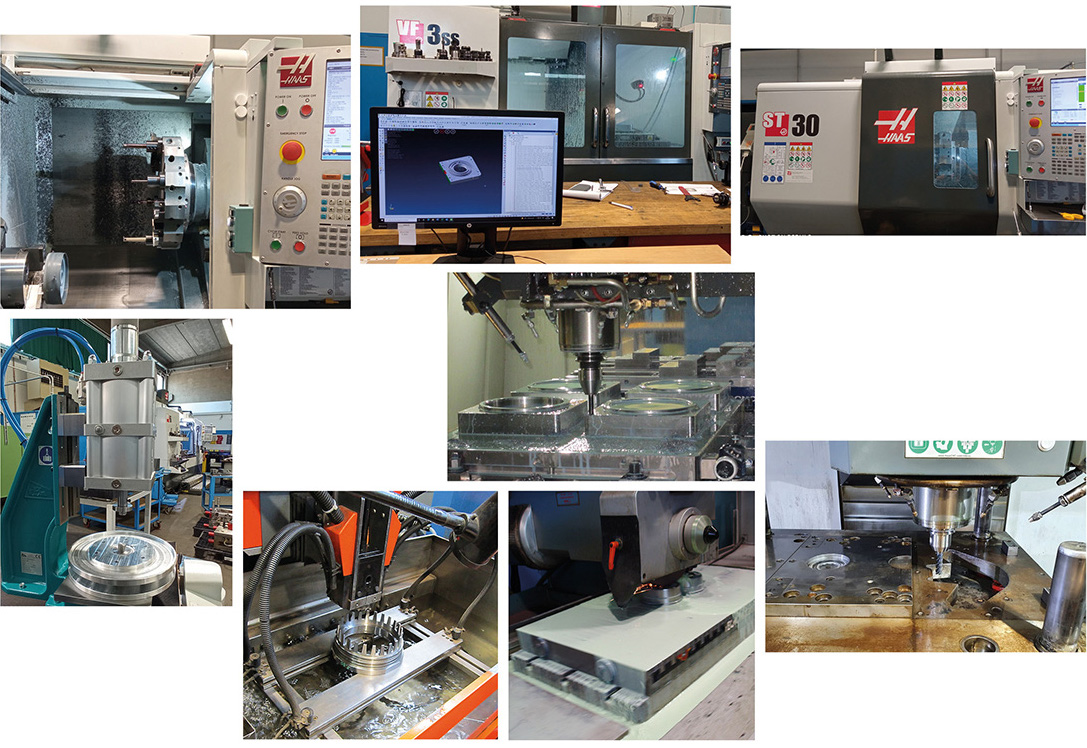

1 HAAS UMC750 (762x508x508), 5 axis machining centre

1 HAAS VM6 (1626x813X762), 4 axis machining centre

1 HAAS VF3SS (1016x508x635), 3 axis machining centre

1 CB FERRARI B15 (850x425x400), 3 axis machining centre

1 RAMBAUDI MG3, milling machine

2 HAAS ST30, CNC turning machines

1 GRAZIANO GR300C, CNC turning machine

1 OMG ZANOLETTI, turning machine

1 CHARMILLES ROBOFILL 2OOO, wire electro-discharge machine

1 CHARMILLES ROBOFORM 400, plunge spark machine

1 ROSA ER-10 ( 1100X600), surface grinder machine

4 VISI MOULD 3D, workstations

2 POSTAZIONI VISI MACHINING 3D, workstations

1 EDGE CAM TURNING, workstation

WE CARRY OUT MAINTENANCE BOTH NORMAL AND EXTRAORDINARY SUCH AS WASHING, PICKLING, CLEANING, COMPONENTS CHECKS, AND RESTORATION OR REPLACEMENT OF WORN-OUT PARTS.