Custom solutions are one of our strong points

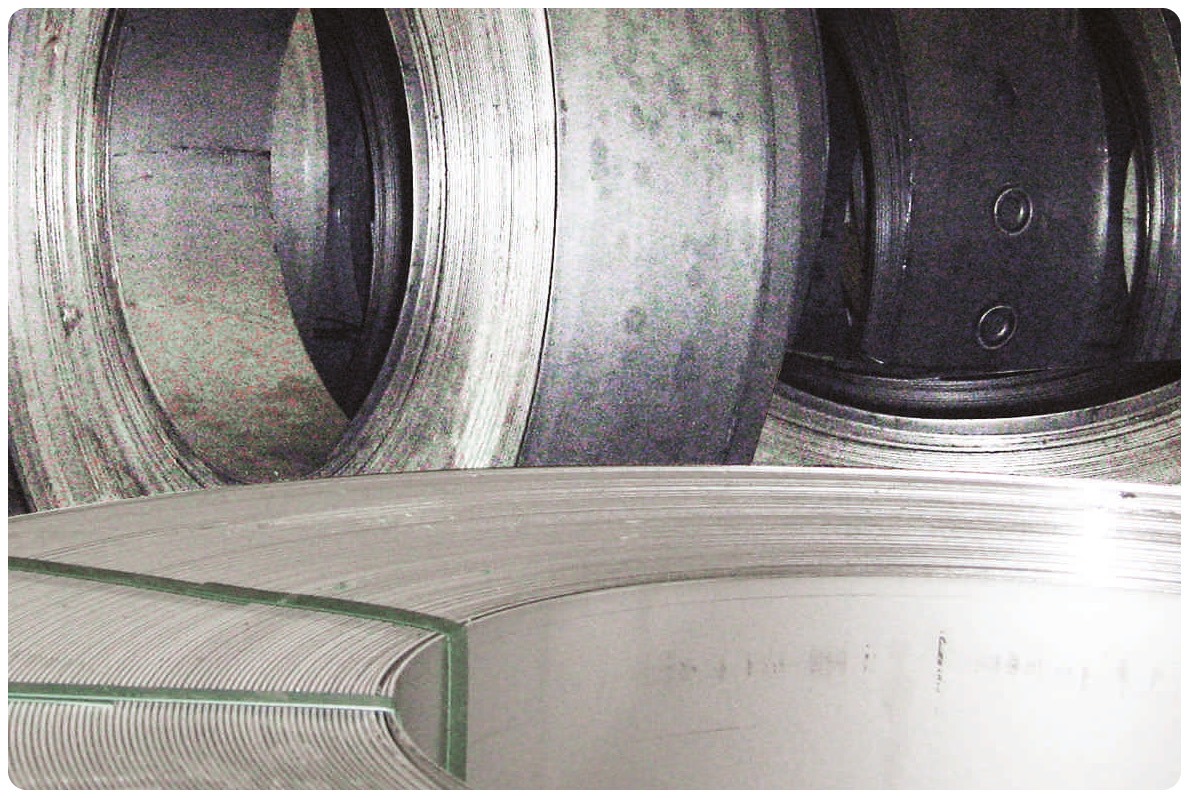

A large part of the improvement and innovation in our products results from working together with our clients. Requests from clients to modify products to their individual specifications and for uses beyond those considered at the original development stage have frequently opened up interesting and mutually profitable opportunities. In the majority of cases, modifications sought by clients are translated into new product ranges or in extension of existing ones. With this objective, we are designing and developing wheels with non-standard dimensions, researching new materials and finding innovative technical solutions in order to adapt our wheels and supports for new uses.

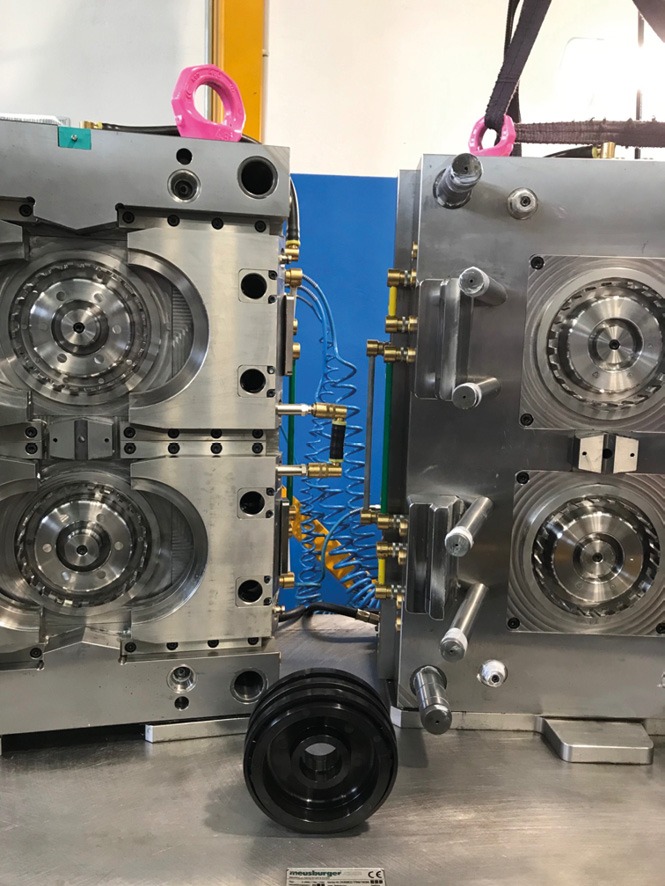

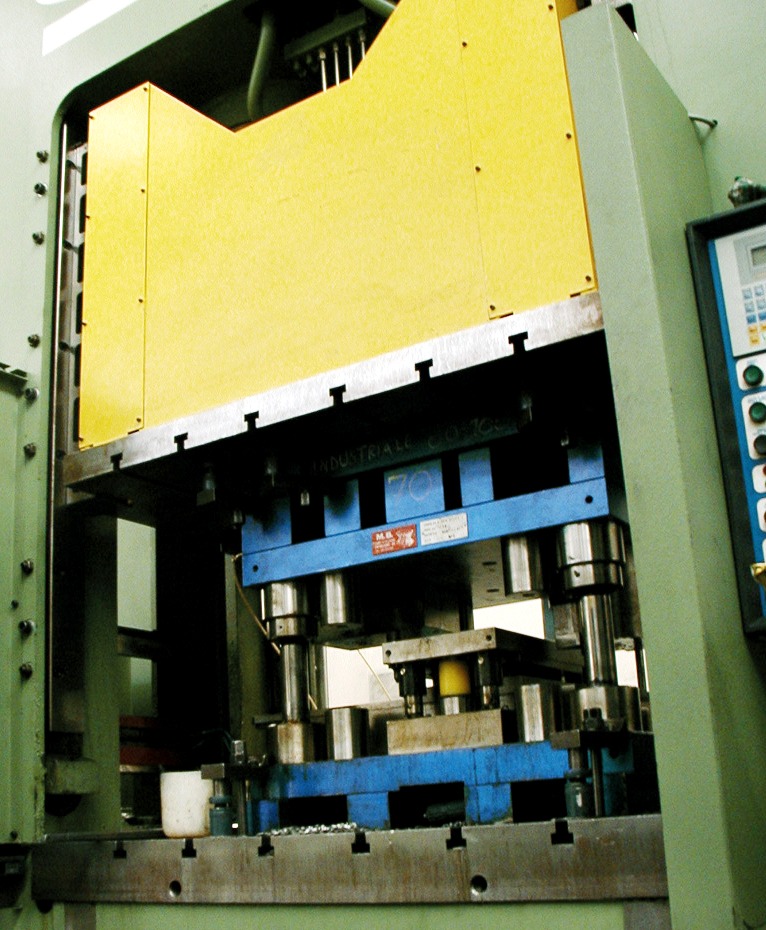

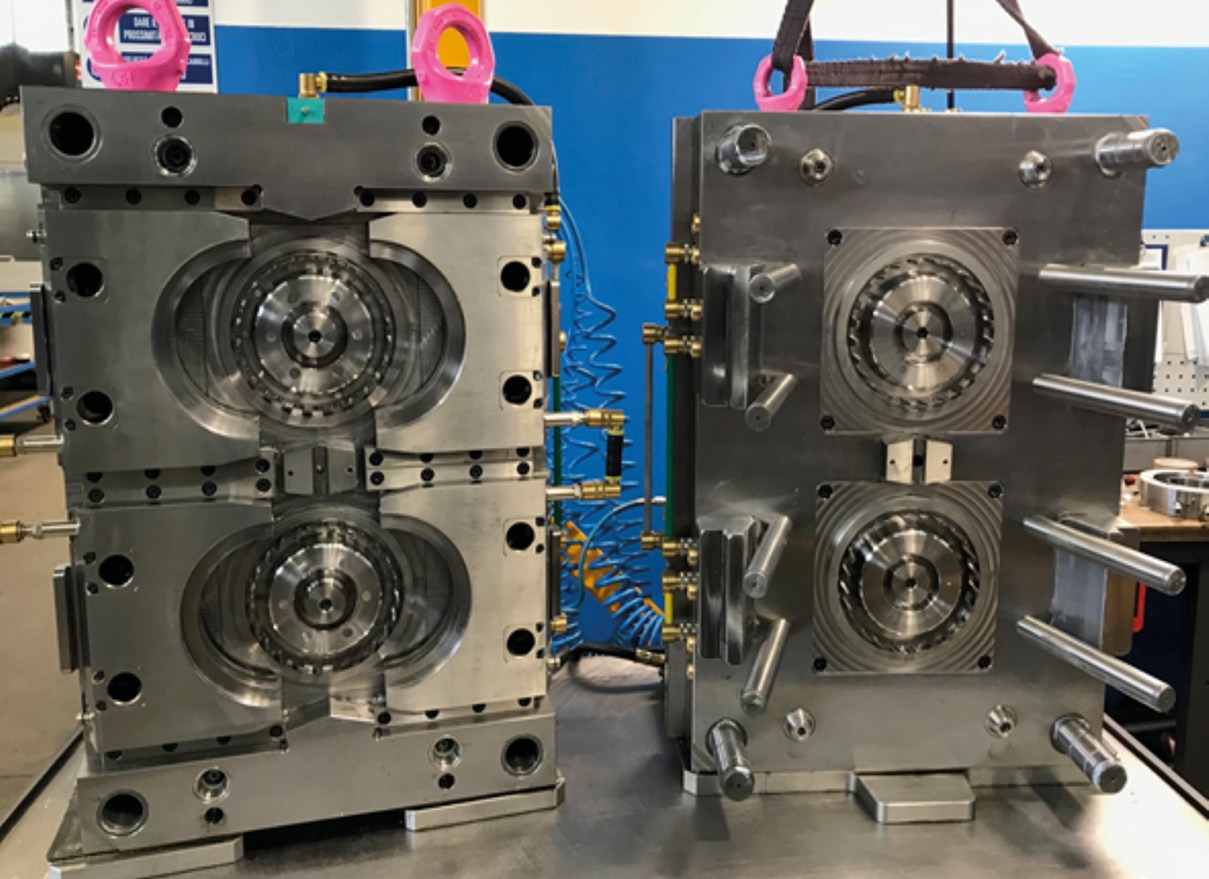

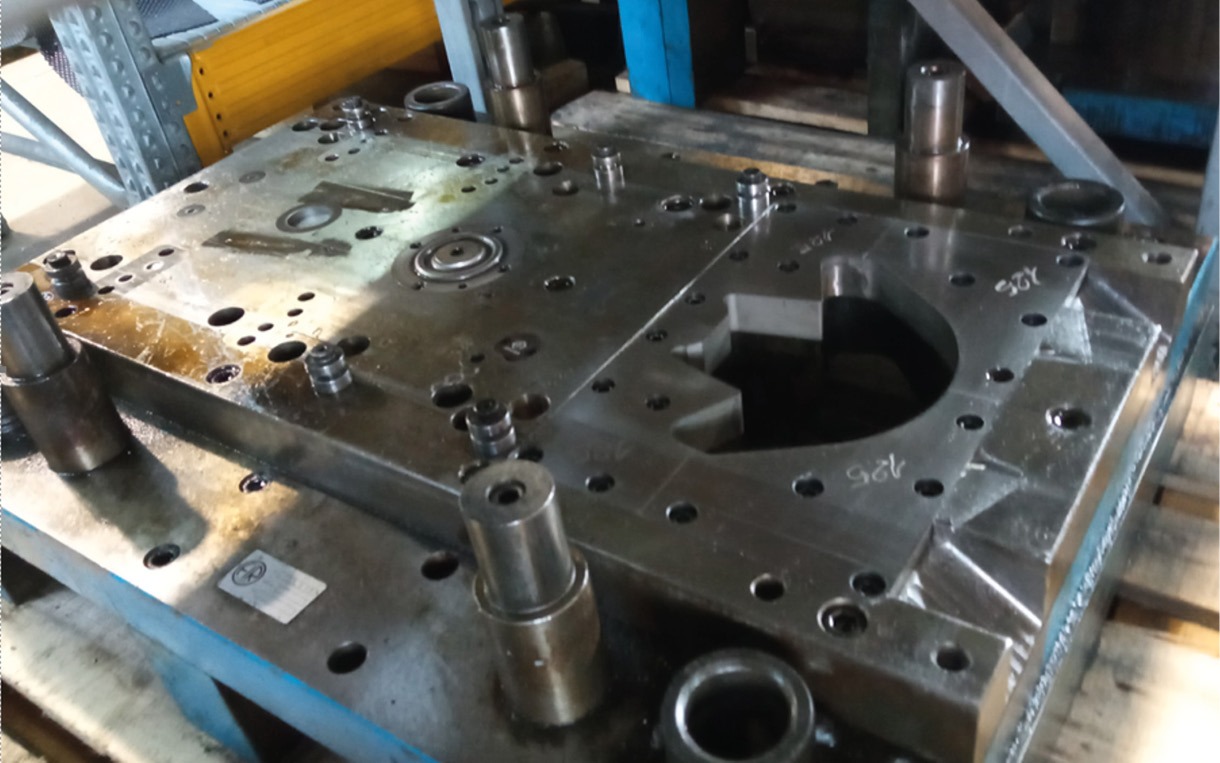

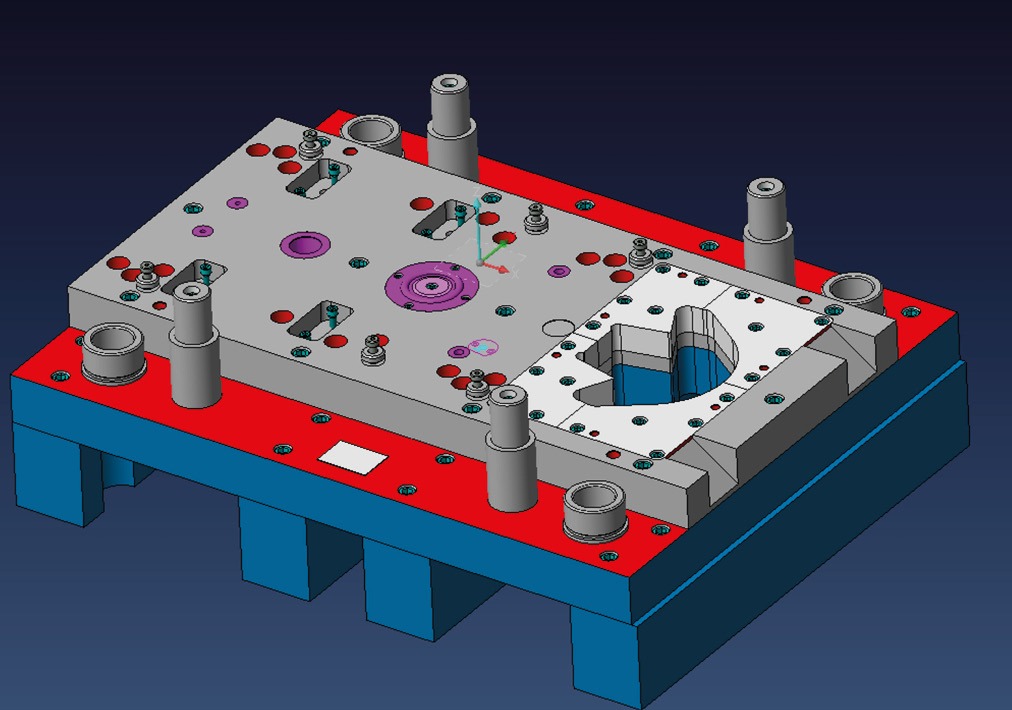

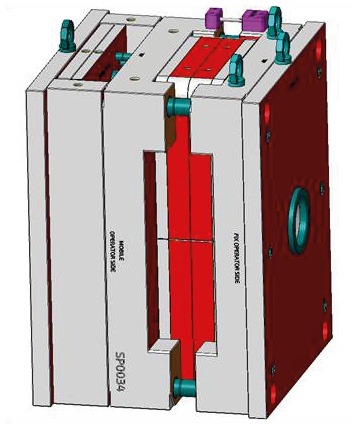

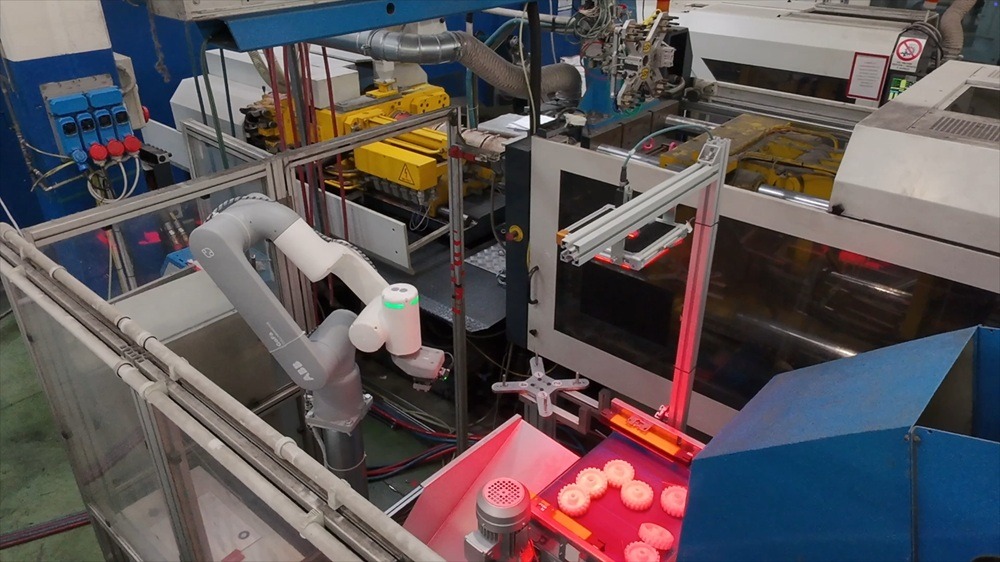

The Engineering division, provides an integrated service of design, modelling, execution and testing of molds for the injection molding of plastic materials and molds for metal molding. This allows us to benefit from a vertically integrated structure giving the capacity to design and produce customized products, from the initial concept up to the finished product, including tooling. All executed in-house.

It is through attention to client requirements and the collaboration of our technical and commercial staff that we are able to ensure continuous improvement and non-stop innovation.

A factory with a high degree of vertical integration:

- we design our products

- we design and construct the molds

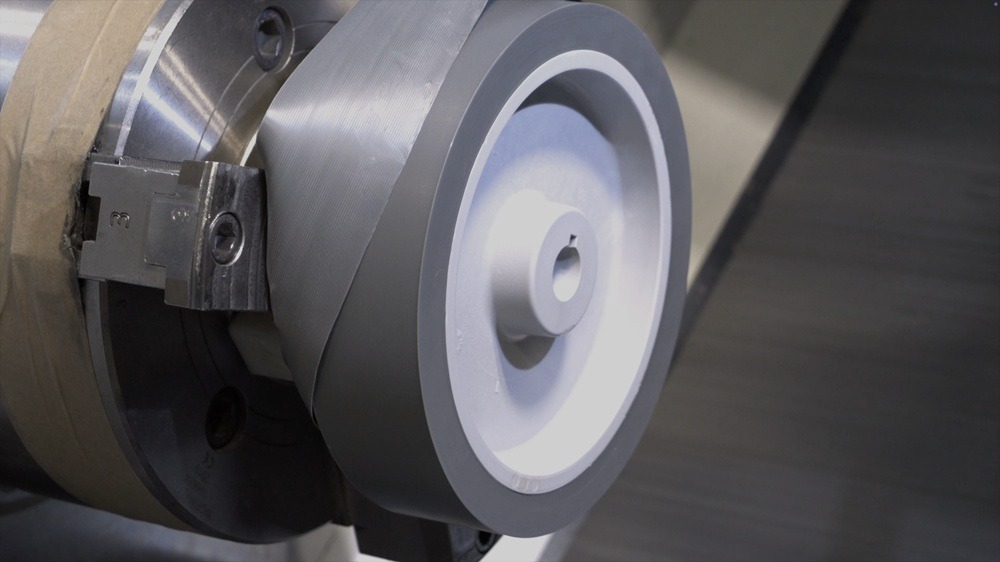

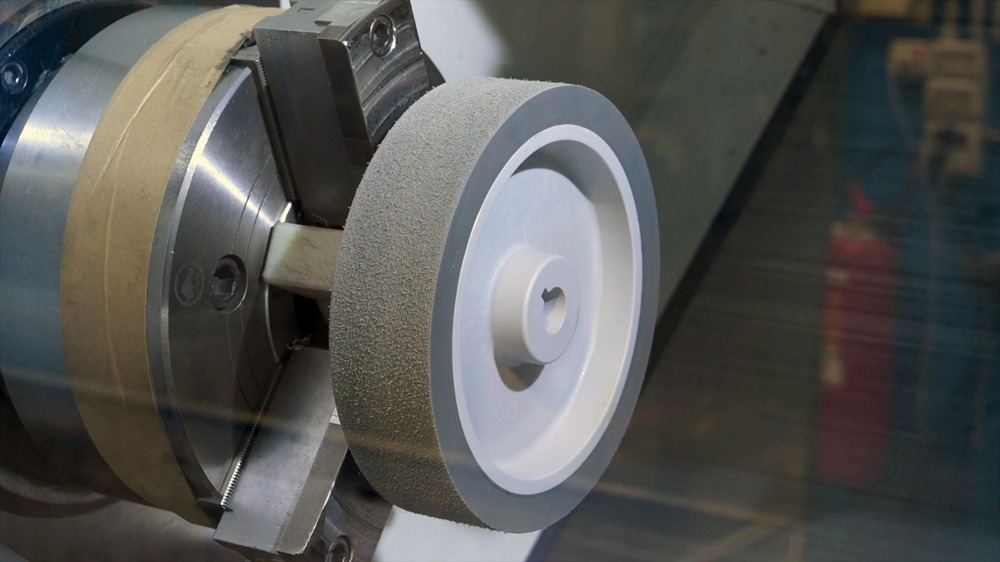

- we mold wheels and brackets

- we carry out the necessary finishing

- we test all in-house.

F.I.R. srl is a leading manufacturer of wheels and casters.

Each day, we commit ourselves, to provide the best value for our customers by using premium raw materials, advanced technologies and qualified personnel. Our aim is to develop innovative products, flexible solutions and superior customer service for safe, smooth and creative mobility systems.

In recent years, the F.I.R. success story has been the result of injection molding of elastic polyurethane. Our wheels are the best choice for electric vehicles, robots, scrubber-driers, AGV, intralogistics and many indoor mobility systems.

Know-how, competence and experience: these are our crucial characteristics

F.I.R. Engineering Division

F.I.R. Engineering is the Tooling Division of F.I.R. srl. It designs and manufactures molds, and it performs precision mechanical processing. F.I.R. Engineering is a highly specialized division with qualified personnel and cutting-edge technology.

- designing and producing single-cavity, multi-cavity, hot runner molds, cold injection molds, sliding core molds, molds for sheet metal blanking, bending, deep drawing and punching, progressive molds.

- carrying out mold maintenance for molds produced by other manufacturers.

- performing precision mechanical processing using CNC machining centres.